焊接渗透缺陷和测量和检查的简化

焊接通常用于用于汽车和飞机等产品的金属连接过程中。可以通过测量在横截面样品上测量焊缝渗透的尺寸以及检查缺陷,例如渗透不足和连接故障来评估焊缝的质量。

钥匙's latest 4K Digital Microscope clearly expresses metal structure boundaries and defective areas even for low-contrast weld cross sections. Also, this microscope can quickly measure 2D and 3D dimensions, and automatically generate measurement results (such as images and values) in a report format, thereby achieving dramatic efficiency improvement.

- 焊缝渗透检查的重要性

- Welding Quality Related to Penetration

- Latest Examples of Using Microscopes to Streamline Weld Measurement and Inspection

- 4K显微镜,可更改焊接测量和检查

焊缝渗透检查的重要性

焊接通常用于与汽车,飞机,铁路汽车和船舶等产品的金属组件连接。对于汽车,连接主要是通过各种类型的电弧焊接,电阻点焊接和激光焊接发生的。这些技术用于车身,框架,发动机,变速器,底盘以及其他在汽车驱动时施加压力的组件。这使焊缝的强度设计和焊缝质量检查的强度通过横截面的维度测量。

焊缝的机械性能和断裂

连接这些基本材料的焊缝(焊珠和穿透性),同时也是金属材料,包括已融化和固化的填充材料(例如焊杆和焊接电线)。

例如,在典型的电弧焊接中,金属结构不仅在焊接金属中不断变化,而且在受焊接热量影响的基础材料的部分中也发生变化。随着这种变化,金属材料的机械性能也不断变化。另一方面,在焊珠表面形成的钢筋具有不连续性。不连续性浓度导致机械性能偏差,从而导致压力浓度引起的断裂。

强度设计和焊接质量

In strength design of metal products, materials are generally selected by assuming the load to be applied to the products and determining the load to be applied to each metallic material. Also, loads applied to welds of each material need be taken into account in strength design, thus setting a standard for welding quality that must achieved.

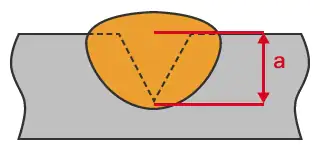

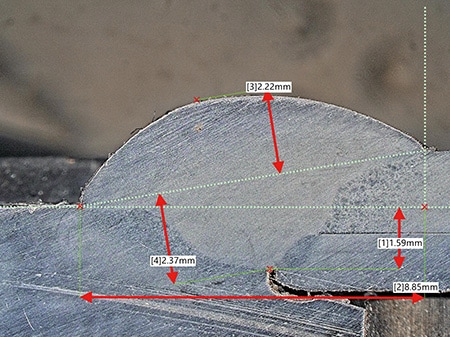

Therefore, it is important to inspect the welding quality on the basis of strength design by measuring, for example, the throat thickness (or throat cross section, the size of the weld bead cross section after welding), the leg length, and the penetration depth. The quality of welds can be evaluated through macroscopic measurement of cross sections after welding.

Welding Quality Related to Penetration

穿透深度和穿透缺陷

The penetration depth is closely related to the joining strength. Any penetration defects on welds, such as inappropriate relationships between the penetration depth and base material, will greatly affect the quality and strength of welding. With butt welding as an example, the following describes typical penetration defects.

- Insufficient penetration

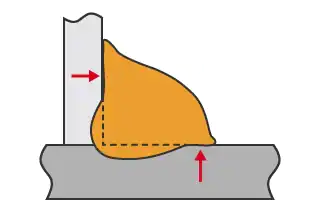

- 与所需的穿透深度相比,由于诸如熔融金属施用不足之类的因素,因此穿透量不足。该图显示了膝盖圆角焊接的示例。在对接焊接中,这种缺陷很容易发生在凹槽的底部。在薄板T恤(水平圆角)耦合的情况下,如果穿透深度为薄板的20%或更少,则渗透被认为是不足的。

- 不完整的融合

- A defect in which parts of the base metal have not been penetrated by the molten metal. The figure shows an example of a thin plate tee (horizontal fillet) coupling. This defect is caused, for example, by the insufficient application of heat to the molten metal and pre-flow of molten metal. In circumferential welding, it is also caused by the preceding and succeeding beads being transferred to lap welding before they have penetrated sufficiently.

完全渗透焊接, partial penetration welding, and their strength

不同的凹槽也会引起不同的渗透模式,从而导致焊缝强度差异。

- 完全渗透焊接

-

完全渗透焊接is a welding method in which the groove of the base material to be joined is united and embedded with molten joining materials (filler rod and welding wire), as with butt welding.

It can be said that full penetration welds are highly reliable in strength design as they have the same proof stress as the base material. On the other hand, they require high welding quality. Particular attention is required at the ends of welds to prevent defects such as undercut welds. It is also important to control and adjust reinforcement because stress concentrates on excessive reinforcement, causing cracking or other such problems.

- Partial penetration welding

- 部分穿透焊接是一种在基本材料上产生部分凹槽的方法。在这种方法中,基本材料仅部分焊接,而完全渗透焊接焊接基本材料的整个板厚度。尽管通常使用完全渗透焊接,但在某些情况下需要部分渗透焊接,例如,由于材料的设计和制造,连接部分相互交织。

但是,由于部分穿透力焊接的焊接强度通常不够,因此需要在弯曲矩或拉伸力的位置进行部分穿透焊接过程中谨慎。因此,焊缝的强度设计以及对实际焊缝渗透尺寸(例如喉咙厚度)是否满足设计条件的测量和检查都特别重要。

Latest Examples of Using Microscopes to Streamline Weld Measurement and Inspection

焊缝的横截面通常在穿透和基本材料之间存在较低的对比度,因此使用常规显微镜的测量很难,并且导致操作员之间的变化。同样,在立体显微镜的情况下,有必要视觉检查刻度并手动输入测量值。

然而,近年来,数字显微镜的技术进步已经解决了常规显微镜的问题,并显着改变了焊接渗透的清晰度和维度测量的效率。188金宝搏下载appKeyence的VHX系列超高定义4K数字显微镜通过清晰的图像和尺寸测量提高了焊缝渗透检查的效率,并由最新的高分辨率镜头,4K CMOS,照明创新和图像处理技术支持。188bet在线

4K高分辨率图像清楚地捕获了穿透和基本材料之间的边界

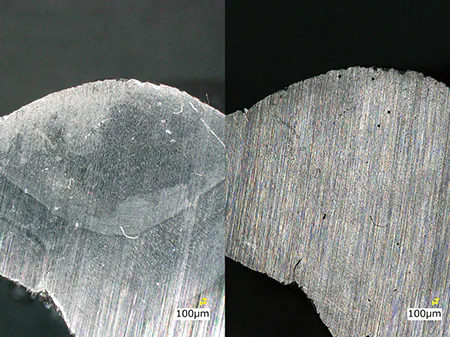

焊缝的横截面有时由于焊接边界对穿透性和基本材料的焊缝边界的低对比度而变得难以进行判断和测量。因此,这些边界无法通过常规显微镜清楚地观察到。

VHX系列4K数字显微镜可以通过高分辨率4K图像清楚地捕获边缘。即使对于很难区分焊接金属和基本材料之间的边界的膝盖圆角焊接的横截面,现在也可以快速,独特地观察清晰的边界边缘,金属结构的差异和缺陷区域。

这些观察结果消除了在传统的维度测量中的混乱,并降低了工作时间,同时提高了检查准确性。

左:高分辨率/右:正常(30 x)

提高焊缝的尺寸测量效率

焊接横截面的维度测量是与强度和质量有关的重要检查。但是,使用常规的立体显微镜,由于基本材料和珠子之间的对比度低,很难判断测量点。同样,需要与内存和手动输入所获得值的视觉匹配,从而导致人体错误和复杂操作的问题。

VHX系列4K数字显微镜在其监视器上具有4K高分辨率图像,可以清楚地表示焊接边界,因此可以轻松地单击“轻松单击点”测量点的操作,启用诸如腿长,喉咙深度和穿透深度等项目的2D维度测量。。您可以在短时间内轻松地完成高临界性,亚微米级测量,从而实现大量工作时间的减少。

此外,最新的自动边缘检测功能可防止操作员之间的测量点的变化。此外,由于功能使用户可以通过从专辑中选择测量和保存的数据来重复维度测量值,因此满足了各种检查需求。

Weld penetration measurement

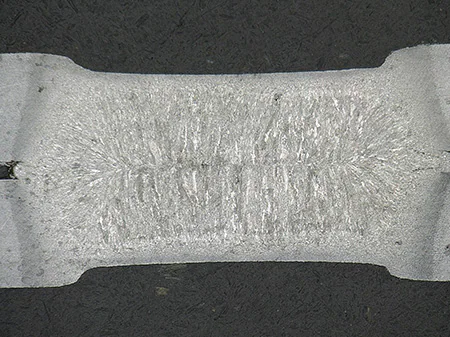

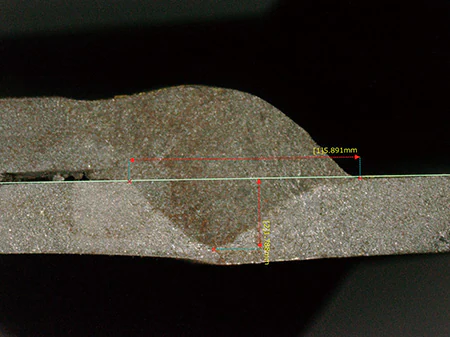

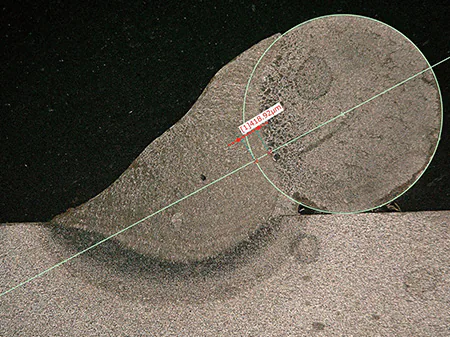

3D尺寸测量和焊珠的3D形状

焊珠具有连续不平衡的形状。如果在珠表面上存在(不连续的)缺陷,例如不足的加固,重叠,底切,凹坑和破裂,则无法获得预期的机械性能,并且可能会发生断裂。但是,传统的显微镜不能使整个不平衡的珠子表面成为焦点,也无法提供评估诸如增强物品等项目所需的高度信息。

VHX系列4K数字显微镜可实现具有不均匀表面的目标的完全集中的观看和3D维度测量。此外,通过显示焊珠的3D形状,您不仅可以从各个角度自由检查形状,还可以测量任何横截面的轮廓。由于可以分析形状和粗糙度,因此您还可以检查焊珠周围的基本材料表面上的飞溅物,裂缝和类似问题。

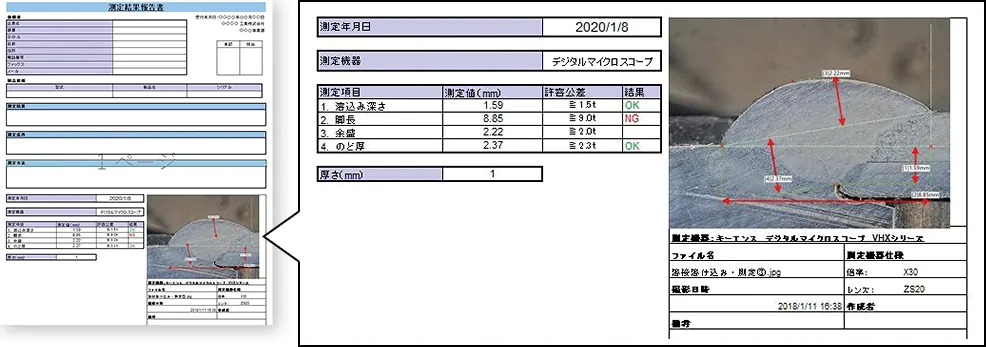

Instant creation of measurement and inspection reports

从传统上讲,运营商不仅必须处理复杂的测量和检查,而且还必须处理报告创建的大量工作量。

The VHX Series 4K Digital Microscope is equipped with a report function. You can also install Excel on the VHX Series, just like a PC. Setting up templates in advance makes it possible to instantly enter not only magnified images, with the dimensions included, but also measured values and pass/fail judgments. These templates dramatically reduce the effort and man-hours required for report creation.

4K显微镜,可更改焊接测量和检查

The VHX Series is a powerful tool that solves problems in conventional measurement and inspection while improving work efficiency. It does so by way of its clarity that can be achieved only with 4K high-resolution images, acquisition of numeric data through high-accuracy measurement, and data saving and utilization. It is equipped with many other advanced functions that were not conventionally available. In addition, many other functions are also provided to meet on-site requirements for speed and accuracy, such as a seamless zoom function that automatically changes the magnification between 20x and 6000x without lens replacement, the Optical Shadow Effect Mode and multi-lighting functions that help express the fine details of uneven surfaces clearly, and automatic templates for repeated measurements.

有关其他产品信息或查询,请单击下面的按钮。