Observation and Analysis of Ceramic Materials

Ceramics are materials that have been around since before resin and metal. While ceramics are hard and resistant to friction and high temperatures, they have been considered unsuitable for use as a material for industrial parts due to their vulnerability to mechanical impacts and rapid temperature fluctuations.

However, in recent years, ceramics that have overcome these shortcomings have been developed and are now used in electrical assemblies (a typical example being multilayer ceramic capacitors (MLCCs)), heat-resistant bearings used in automotive and aircraft engines, building materials, and other key parts.

本节介绍了我们最新4K数字显微镜进行的观察和分析陶瓷材料产品的示例。

- The Need for Observation and Analysis of Ceramic Material Products

- 使用我们最新的4K数字显微镜观察陶瓷材料产品的示例

- 一个显微镜支持从观察和分析到报188bet在线告生成的一切

The Need for Observation and Analysis of Ceramic Material Products

Surface mounting on chip components became possible in the mid-1980s, which paved the way to use ceramic capacitors as chip components. Since then, ceramic capacitors have become smaller in size alongside the increasing integration density of PCB mounting. The sophisticated techniques and production systems that allow for accurate stacking of hundreds of dielectric sheet layers within a mere 1 μm have bolstered electronics in every field. Nevertheless, the miniaturized parts were more prone to having poor insulation between the internal electrodes due to cracks from warping PCBs and scratches in the dielectric sheets.

In terms of building materials, there are functional ceramic tiles with super hydrophilic and antifouling properties. Because ceramics used in building materials are required to be highly heat resistant and flame proof, composition analysis is essential for maintaining quality.

随着使用中的组件变得更加复杂和复杂,对陶瓷材料的观察和分析的需求正在增加。

使用我们最新的4K数字显微镜观察陶瓷材料产品的示例

在大多数情况下,陶瓷材料产物的表面具有较低的对比度,这使得使用光学显微镜很难观察表面。

但是,VHX系列的高分辨率镜头和4K图像传感器可以对陶瓷和其他低对比度材料进行高级观察。

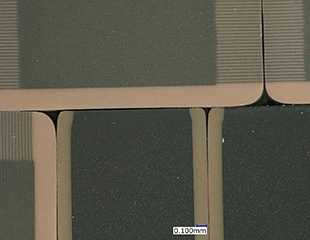

Example of observing a multilayer ceramic capacitor (MLCC)

MLCC在1微米内使用数百个陶瓷层作为介电片。可以通过使用磨损去除包装来观察到嵌入在这个小区域的陶瓷。

即使是在安装时出现的小裂缝也可能从机械影响和衰老中形成更大的裂缝,这些较大的裂缝也会导致绝缘失败。绝缘不良会导致组件故障,热量产生和/或火力。在检查过程中,由于放大或分辨率不足而忽略了细微的裂缝已成为一个严重的问题。

While minute exterior problems on ceramic material products tend to have low contrast that makes them difficult to observe, the VHX Series 4K Digital Microscope can observe such defects by comparing the images taken using both darkfield and brightfield lighting setups. This comparison enables a clear capture of cracks and insulation failures.

Even when the resin-coated sample had an uneven surface due to insufficient polishing, the deep depth of field provided by the high-resolution lens contributes to a clear imaging of even submicron-order cracks.

Observation of glass fiber in ceramic building material

玻璃fiber is a widely used inorganic material characterized by its heat and corrosion resistance as well as excellent elasticity and stiffness. High-functionality building materials have been developed by including glass fiber in the ceramic fibers. These materials have good heat insulation, heat resistance, and fire-proof properties. Some examples of their use can be seen in flame-retardant curtains and for sealing heat from boilers and other industrial furnaces.

编织成棉状材料的玻璃纤维具有高峰,深山谷和低对比度。这些问题阻止了使用常规显微镜进行准确的观察。

Keyence的VHX系列高清4K数字显微镜采用了最新技术,包括高分辨率镜头和4K CMO。这些技术使VHX系列能够观察和分析具有清晰4K图像的陶瓷建筑材料中的玻璃纤维。

The Depth Composition function can fully focus the entire target, regardless of its uneven surface. The High Dynamic Range (HDR) function captures multiple images at varying shutter speeds to obtain an image with high color gradation, thereby making it possible to perform observation with images sporting higher levels of detail and contrast, which were conventionally inaccessible due to limitations in resolution and contrast.

VHX系列还使用高分辨率放大图像来支持2188bet在线D和3D测量,这有助于高度准确,快速地执行分析所需的一系列任务。

观察陶瓷边缘表面上的划痕

常规显微镜s provided different views depending on the angle of lighting. These different views led to cases where scratches on low-contrast ceramic material edges were overlooked.

With the VHX Series, omnidirectional lighting data is automatically captured, and the most suitable image can be selected for additional analysis. Furthermore, after capturing the image the lighting direction can still be manipulated using the mouse, so scratches and other defects can be illuminated and observed.

一个显微镜支持从观察和分析到报188bet在线告生成的一切

The VHX Series high-definition 4K Digital Microscope offers excellent efficiency compared to conventional optical and digital microscopes and makes it possible to eliminate human errors and ensure accurate observation and analysis.

由尖端的光学图像处理和自动化技术生成的高清4K图像允许自动测量和对具有简单操作的陶瓷材料产品进行计数。这有助于每次产生快速,复杂的分析结果。

使用报告功能,可以轻松地将捕获或测量的数据作为用固定格式输出。这不仅对于质量保证,而且对于确定可能出现的任何问题以及随后的流程改进而有用。

VHX系列配备了许多其他高级功能,可以成为陶瓷材料产品缺陷分析的有力合作伙伴。有关其他产品信息或查询,请单击下面的按钮。