Friction, Wear, and Abrasion Tests and Analysis

Friction occurs between moving parts, and is commonly analyzed in parts that come into contact with one another during operation, such as power trains in automobiles.

The friction causes heat generation and wear in these parts. Heat generation and wear derived from friction account for most mechanical system failures, and economic losses due to such failures are not small. To reduce such losses, tribological tests are conducted to evaluate parts and properties of the parts materials.

本节介绍了测试和测量方法,以及从摩擦学的角度使用Keyence的4K数字显微镜解决问题的最新示例 - 相对运动中相互作用的表面之间的磨损和摩擦科学。

- 摩擦,磨损和耐磨性测试

- Friction, Wear, and Abrasion Resistance Testing Methods

- Tribological Tests

- Latest Examples of Observation for Friction, Wear, and Abrasion Resistance Tests

- The Latest Tool for Quickly Responding to Market Demands

摩擦,磨损和耐磨性测试

In this test, a test piece and an interfacing surface are subject to interaction in relative motion to measure the coefficient of friction* and the wear volume.

In industries where parts come into contact with one another, it is critical for research and development to evaluate the changes in the material by means of friction, wear, and abrasion. Testing and analysis is required for quality assurance of motors, bearings, lubricants and many other products.

摩擦系数:值,显示了我pact of the contact surface on frictional force. It does not have any unit and is represented by μ (mu). Classified into coefficient of dynamic friction and coefficient of static friction, the value varies depending on the object and surface treatment.

Friction, Wear, and Abrasion Resistance Testing Methods

摩擦测试测量摩擦特性以及耐磨性测试,通常使用摩擦系数计算结果。另一方面,磨损测试测量摩擦引起的条件变化,结果是从相互作用表面上的变形,划痕和凹痕中获得的。

There are several ways to measure the coefficient of friction: by measuring the frictional force with a gauge, by measuring and converting the load power of the driving motor, by calculating from the behavior of vibration damping* by friction, and by calculating the maximum static frictional force* based on the angle at which an object placed on a slanted surface starts sliding.These tests check not only for wear and friction but also for the effectiveness and deterioration of lubricants.

Vibration damping: Vibration decreasing with time. Also called vibration attenuation.

Maximum static frictional force: Frictional force generated when a stationary object is moved. In contrast, the frictional force that arises during movement is called dynamic friction, and the friction that occurs on balls and needles in bearings is called rolling frictional force.

Tribological Tests

Frictional resistance can be minimized by taking a multi-faceted approach that includes material mechanics, fluid mechanics of lubricants, and thermodynamics to measure how the surface is affected by heat.

Tribology is the science of examining and evaluating the impact of friction from a wide-ranging perspective. The tests conducted to evaluate the relevant properties are called tribological tests.

The need for tribological tests

摩擦产生的热量和由于摩擦而损失的材料导致机械电阻,据说这是机器断层和故障的最大贡献者。减少和控制摩擦和磨损不仅是一种预防问题的方法,而且是提高机械系统的可靠性和性能,从而减少经济损失的核心技术。

Characteristics of tribological tests

Wear and friction tests are said to often give completely different characteristic values when the shape of the specimen, test method, and atmospheric conditions change, even when testing the same material. Therefore, for wear and friction tests, it is necessary to understand the conditions under which the actual target impact is caused and conduct the tests using similar conditions. The performance of a lubricant depends significantly on the physical properties of the lubricant and the chemical properties of the interface. In particular, solid lubricants* have a higher load capacity than oil and grease and therefore are also used as additives to oil and grease.

Tribological tests are conducted under conditions close to the usage conditions, reproducing the actual environment the friction to be observed occurs in. The materials and shape of the parts are closely observed and evaluated during testing.

Solid lubricant: Solid substance that protects the material surface from friction and reduces wear and friction. Examples of solid lubricants include molybdenum disulfide, graphite, and PTFE (Polytetrafluoroethylene).

Latest Examples of Observation for Friction, Wear, and Abrasion Resistance Tests

Test pieces and interacting parts in wear and friction tests are generally three-dimensional and have highly reflective surfaces. When using conventional microscopes, the operator must be highly skilled in order to find proper focus and mitigate the reflection from the surface. Additionally, quantitative evaluation is not possible.

得益于技术进步,数字显微镜解决了常规显微镜的问题,并显着改善了对摩擦和磨损测188金宝搏下载app试的评估。

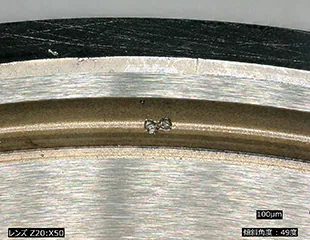

Efficient observation of deep indentations in bearings

Indentations occur when some sort of impact is applied to the bearing. When the observation surface on the bearing is not flat, high-magnification with a conventional microscope is very difficult, and time-consuming focus adjustments must be performed.

The high-resolution HR lens and motorized revolver of the VHX Series 4K Digital Microscope enable a seamless zoom function that quickly switches between lenses according to the magnification in the range of 20x to 6000x, eliminating the need for lens replacement.

- A: Observation using a digital microscope

- B: Observation using a microscope

- C: Observation of an indentation on the front surface

- D: Observation of an indentation on the back surface (500x)

The real-time composition function automatically performs depth composition to bring the entire target into focus. With this function, you can easily perform accurate, efficient magnified observation, appearance inspection, and evaluation using fully-focused 4K images.

Additionally, the VHX Series automatically tracks the lens magnification, ensuring accurate data and record management.

Observing and measuring damage on surfaces

When performing observation and measurement, previously testers needed to switch instruments, leading to long test times.

The VHX Series 4K Digital Microscope not only captures high-magnification images, but also allows for measurements and quantification that is not possible with conventional microscopes. Flaking*, pitting*, and other damage to the surface can be observed and 2D and 3D measurements, as well as surface roughness, can be performed with a single device.

Flaking: Rough and coarse texture caused by peeling in the raceway surface and the rolling element surface that occurs due to the rolling fatigue of the material.

Pitting: Speckle-like holes with an approximate depth of 0.1 mm that appear on the raceway surface.

Observing wear on reflective surfaces

Test pieces that are worn due to friction typically have a highly-reflective surface, making observation and imaging difficult.

The VHX Series 4K Digital Microscope has glare removal and ring-reflection removal functions that eliminate reflected light. The new 4K Digital Microscope enables users to distinguish between fine hairline scratches, friction-inflicted dents, and adhesions to allow for a more accurate understanding of the wear and friction conditions.

A single microscope for everything from observation to 2D and 3D measurements

With conventional observation means, testers need to focus on multiple different parts of three-dimensional targets, which can lead to damage being overlooked and different operators obtaining different results. Moreover, only 2D measurements can be obtained, making it impossible to understand the depth of surface defects and scratches.

VHX系列4 k数字显微镜不仅紧密相联的ws for magnified observation and 2D measurements, but also is capable of capturing 3D shapes and performing profile measurements. Irrespective of the skill level of the tester, the VHX Series offers simple measurement of 3D shapes, improving analysis capabilities.

The Latest Tool for Quickly Responding to Market Demands

To respond to tribological evaluation needs, in addition to the expanding demands in wear and friction tests, it is necessary to establish R&D, quality improvements, and manufacturing processes based on fast and accurate inspection data.

The VHX Series high-definition 4K Digital Microscope offers excellent efficiency compared to conventional microscopes and ensures higher-accuracy observation, analysis, measurement, and evaluation with just one machine. Equipped with many other advanced functions, the VHX Series can be an effective tool for industries that require both quality and speed.

有关其他产品信息或查询,请单击下面的按钮。