Welding robot control

This page introduces welding robot control, including controlling robots by teaching and by using sensors.

Controlling robots by teaching

教学是指导机器人有关焊接操作的过程。引入机器人是必不可少的。教学可以通过两种方式完成。在在线教学中,机器人实际上是为了学习操作而操作。在离线教学中,将使用CAD或其他方法创建的3D数据和操作加载到机器人的内存中。

尽管教学是定义机器人操作的重要过程,但它需要大量的工时。在线教学变得越来越普遍,因为它需要相对较少的人工时间来教学。

在在线教学中,机器人实际上是为进行焊接而操作的,并使用传感器检测到运动。用传感器检测到的运动作为程序存储。播放存储的操作(教学播放)实现了机器人焊接。

In the process of robot welding, you can improve the accuracy of automatic welding by using non-contact sensors as eyes for the robot to performtracer control by following weld lines或者measurement of groove shape.

Controlling robots with sensors

Control with contact sensors

When thebase material到达线上,连接在电极或火炬末端的探头或电线跟踪表面并检测焊接位置。通常使用两种类型的接触传感器:接触探针传感器和电线触摸传感器。

A contact probe sensor detects the welding position by applying its probe that moves together with the torch to thegroove并使其追踪weld line.

电线触摸传感器通过电线通过弱电流,该电流用作filler materialand makes the wire touch the base material to detect relevant positions (such as welding start/end positions or the position of the焊缝) in the way as a visually impaired person uses a cane. It has the disadvantage that, when the angle or opening width of the groove fluctuates, detection may take time because the sensor needs to repeatedly sense the contact points.

Detection examples using a contact sensor (wire touch sensor)

- Stick sensing

-

- 差距感测

-

- 示例凹槽开口宽度发生变化

-

Control with non-contact sensors

Non-contact sensors used for robot welding include arc sensors and laser displacement sensors.

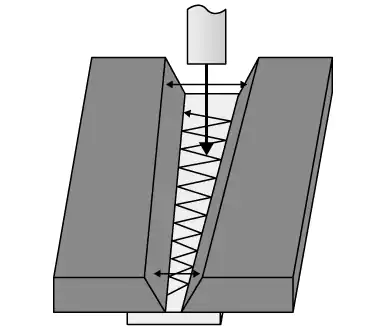

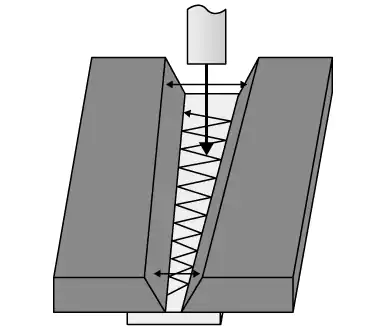

电弧传感器用于消耗电极型电弧焊接以控制焊接电流,而电极weaves沿着凹槽或根据电弧电压的变化来控制火炬的位置。成本相对便宜,但是根据工件的材料,可能无法控制示踪剂。通常,ARC传感器不适合检测凹槽形状。

On the other hand, laser displacement sensors are displacement meters that use laser beams and optical sensors. They can detect and output more information at faster speed compared to other sensors. They can be used for rapid tracer control of weld lines and can measure the groove shape and feed it back to the control in real time. The improved accuracy of automatic welding and shorter processing time has led to an increase in the adoption of laser displacement sensors.

Laser displacement sensors can be classified according to the laser emission method. One type oscillates the beam spot to irradiate the target and the other type uses a laser line to irradiate a large area. For example, in thetailored blank (TB)process, which uses laser welding to join multiple steel sheets with different materials and properties in complex ways to make materials for press working, a laser displacement sensor using a slit light allows quick and accurate detection and control of the weld line.

使用蓝色激光可以检测的传感器the shape of even焊接池that are red from the heat immediately after welding. This improves the quality of automatic welding through real-time optimization of various parameters that affect the amount of deposition, such as the voltage and current of the welding power supply and welding speed.

- A laser sensor covering a large area allows measurement and output of the shape, position and angle of the groove with a single sensor head.

-

使用LJ-X8000系列高速2D/3D激光扫描仪的凹槽控制示例。