Measurement/inspection of weld surface

除了视觉检查外,还有几种焊接表面检查的方法,例如磁颗粒测试(MT),渗透剂测试(PT)以及使用视觉系统或激光位移传感器进行检查。

This page introduces welding surface measurements and inspections.

Contact-type surface inspection

- 磁粉探伤(太)

- 该方法适用于在强磁料(例如铁和钢)表面上和附近检测缺陷。当焊接工件被磁化时,在磁化区域中出现不连续性,在该区域中存在缺陷,在表面或浅层地下(表面约2至3 mm)中存在缺陷。磁通量从零件泄漏,并沿着不连续的边界引起磁极。当将磁性颗粒施加到该状态下的焊缝表面时,它们会变成微小的磁铁,并将其吸引到缺陷周围的磁极。颗粒形成一个磁性粒子图案,显示一条线比实际缺陷的宽度厚数几到十倍,从而可以视觉观察瑕疵。

- Penetrant testing (PT)

- 该方法可用于几乎所有材料的表面检查。可见的颜色或光泽(渗透剂)的高度穿透性液体被应用于焊缝的表面。液体渗透到缺陷中后,将开发人员施加将液体抽出并扩大缺陷,从而可以视觉观察。

常规的非接触式表面检查

表面检查是通过经验丰富的焊接工人在视觉上进行的。这种视觉检查存在各种问题,包括需要大量工时,难以确保工人拥有足够的技能和经验以及人为错误的可能性,例如忽略的缺陷。

Using a vision system allows inline inspection which increases efficiency. The problem is erroneous detection due to the influence of ambient light around the sensor or color irregularities of the weld.

具有激光位移传感器的非接触型表面检查

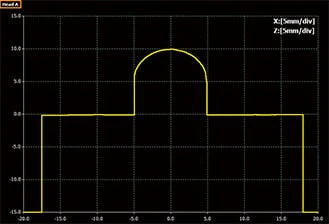

Thebead根据发射到焊接表面的激光的反射检测形状。

激光位移传感器通常需要最佳的反射光,以确保稳定的形状检测。常规的典型激光位移传感器根据从目标的整个表面反射的接收光强度调节目标的光量。因此,在测量曲面表面和具有不同颜色的表面时,由于反射光的差异而引起的错误检测问题。

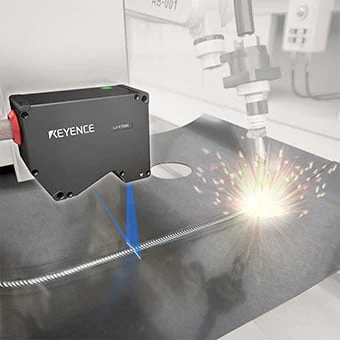

LJ-X8000串联高速2D/3D激光扫描仪通过从传感器头上发射线激光器并使用灯截面方法来检测珠子的形状,并使用基于反射的光测量横截面形状的光截面方法。它的光接收元件的动态范围比常规模型宽2400倍,即使目标焊缝具有弯曲的表面,光泽或颜色不规则,也可以准确识别。

能够进行高速采样的紧凑型传感器头适用于内联测量。

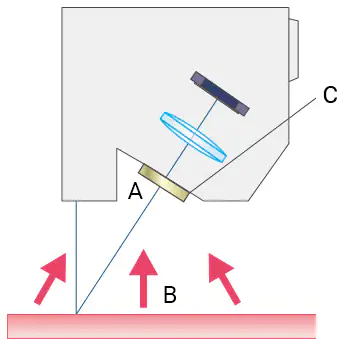

Detection mechanism of the light-section method

Laser light is spread into a wide beam by a cylindrical lens and diffusely reflects on the surface of the target. This reflected light is focused into an image on the HSE3-cmos, providing high sensitivity and wide dynamic range. This image is used to detect the changes in position and profile and measure the displacement or shape.

- Semiconductor laser

- 圆柱形镜头

- 2d Ernostar镜头

- HSE3-cmos

- GP64处理器

Wide dynamic range ensuring stable detection

Conventional displacement sensors required the adjustment of the laser power or exposure time when the reflected light fluctuated. The LJ-X8000 Series has a wide dynamic range to allow accurate profile recognition without being affected by the difference in the reflected light intensity caused by the inclination or gloss of the measurement surface.

LJ-X的配置文件检测

Profile data not affected by brightness difference

Blue laser not affected by hot targets

Typical red laser displacement sensors have a band-pass filter in front of their receiver that passes light of around 650 nm only. When the target is a red-hot steel plate, the wavelength components of the radiant light are mostly between red and infrared. This means that the detection is greatly affected by the ambient light.

LJ-X8000系列采用了蓝色激光器,并配备了一个频带过滤器,该滤波器仅通过405 nm的光线。这允许在焊接后立即测量甚至受到红色和红外之间波长成分的影响的热目标。

- 反射的蓝色激光灯

- Radiant light from hot targets

(including many wavelength components between red and infrared) - 带通滤波器仅通过405 nm的光线

(preventing the influence of the wavelength components between red and infrared)

Unlike conventional cameras or typical laser displacement sensors, the LJ-X8000 Series achieves stable profile detection without being affected by sparks or other optical noise generated during welding or the radiant light from hot-red steel plates immediately after welding.

这使得,example, high-speed inspection of bead shape immediately after welding by tracking the torch in the welding process of量身定制的空白(TBS).

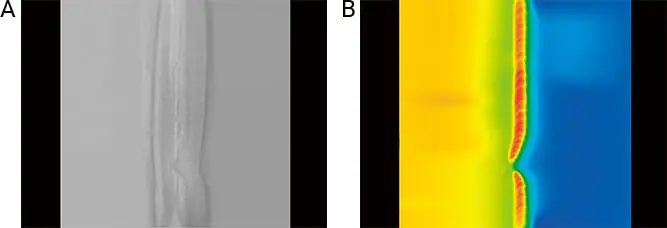

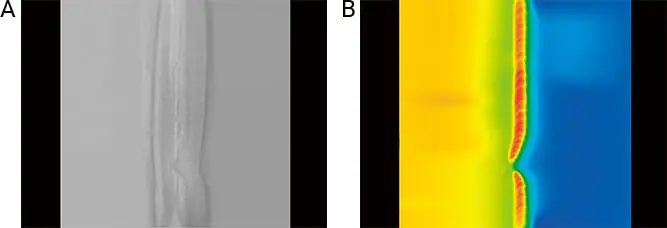

- Comparison of bead shape detection in tailored blank welding

-

- A. Conventional camera

- Measurement was difficult due to unstable surface conditions such as color irregularities and gloss of the target.

- B. Laser displacement sensor (LJ-X8000 Series) + Image processing

- Bead shape can be measured stably without being affected by the surface condition of the target.

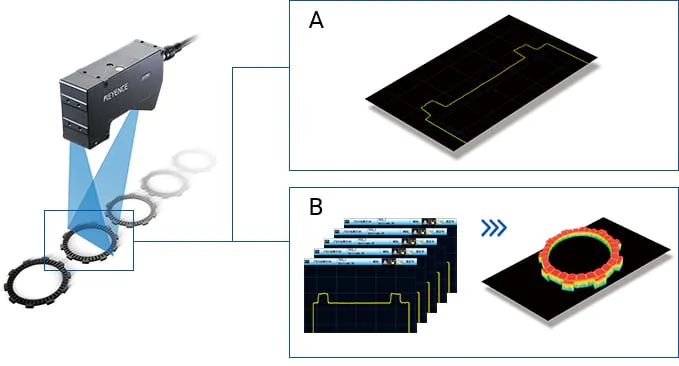

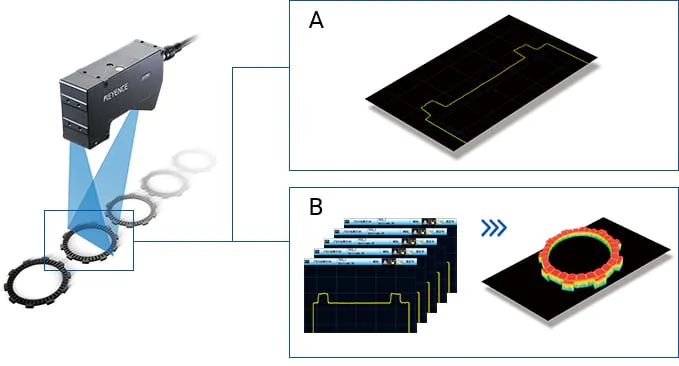

In this way, the LJ-X8000 Series allows non-contact measurement of intact shape of weld beads. This can be applied to:

- 2D shape inspectionfor defective weld beads (such asundercut,重叠,insufficient reinforcement, orcracking)

- 3D shape inspectionusing image processing and analysis of continuous cross-sectional shape data to achieve further detailed inspection such as finding minute表面缺陷.

- Examples of 2D/3D shape inspection using the LJ-X8000 Series

-